Total Customisation: the value of co-engineering

Co-engineering: designing transmission systems based on real-world application requirements

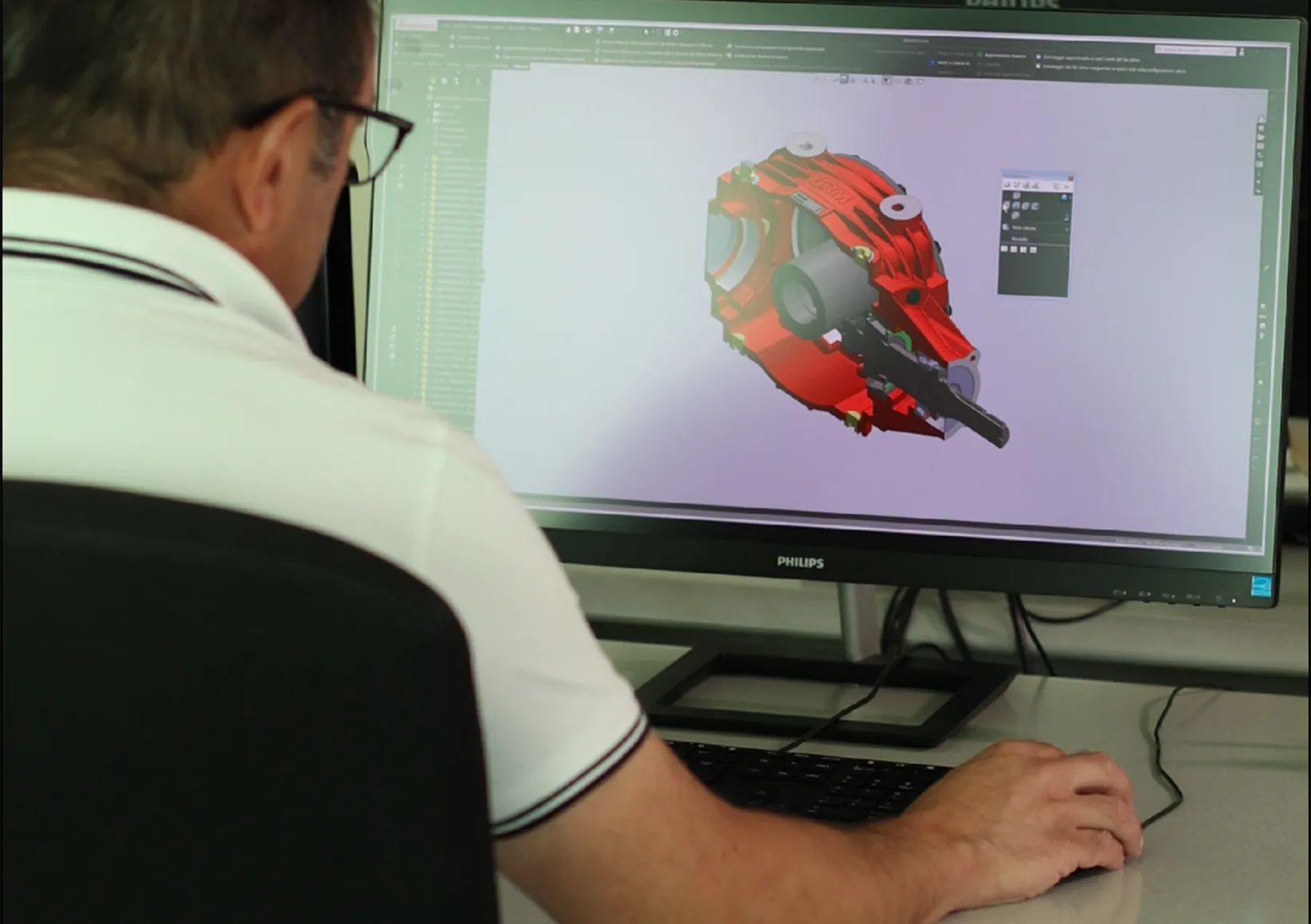

In today’s market, real technical differentiation for OEM manufacturers comes from the ability to obtain tailored mechanical solutions. EuroBRM has developed a structured co-engineering process that actively involves the customer’s technical team from the very beginning of the project.

Each transmission system is engineered from specific functional and kinematic requirements: shock loads, mechanical layout, torque profile, critical frequencies, environmental factors, and dimensional constraints. The result is a drive shaft + gearbox system engineered for perfect integration with the final machine.

EuroBRM process phases

Joint technical analysis: definition of actual operating parameters.

Collaborative design

(3D CAD, FEM simulation, rapid prototyping).

Dynamometric bench tests and in-field validation.

Installation optimization and OEM final commissioning support.

Why co-engineering is a competitive accelerator

EuroBRM enables clients to anticipate design risks, reduce development time, optimize costs, and ensure reliability from the prototyping phase. This approach has led to the creation of custom systems for leading European manufacturers in the agricultural, forestry, and municipal machinery sectors.